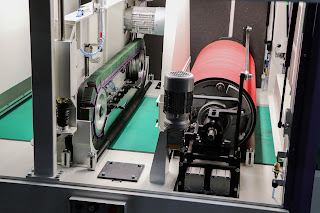

The new DM1100 DC debars and edge rounds inside and outside contours of thick steel parts cut by laser, plasma or oxyfuel. This deburring machine has a contact drum and a double cross belt station which performs edge rounding leaving soft and clean edges.

Burrs are grinded away from the edges with a powerful contact drum. This deburring drum has a large diameter with an extra soft rubber of 20SH for heavy burrs and thick material. The dry concentrate the pressure in the edges where the slag is located, leaving the surface of the material slightly touched only.

On the control panel, you can control all the options for the deburring drum station: fluctuation to cope with different metal tolerances and roller oscillation in order to improve abrasive paper lifetime.

The edge rounding station consists of a set of two counter-rotating edge rounding cross belts. The opposite rotation enables the edge rounding of all the contours: inside and outside. The result after this station is a soft edge.

This deburring machine features a magnetic table with 600mm width section. This area is essential for small steel parts processing to guarantee that even with substantial debarring pressure the parts will not move.

DM1100 DC machine includes as standard an automatic thickness measurement. The news developed system enables to easily slide the laser beam through the conveyor ti select the spot where the measurement will be done. The information of the thickness is sent directly to the PLC. There is also the possibility of integrating extra stations for oxide removal or even double side edge rounding.

If you need more information about this machine please send an email to marketing@nsmaquinas.pt or contact us through contact page.

Burrs are grinded away from the edges with a powerful contact drum. This deburring drum has a large diameter with an extra soft rubber of 20SH for heavy burrs and thick material. The dry concentrate the pressure in the edges where the slag is located, leaving the surface of the material slightly touched only.

On the control panel, you can control all the options for the deburring drum station: fluctuation to cope with different metal tolerances and roller oscillation in order to improve abrasive paper lifetime.

The edge rounding station consists of a set of two counter-rotating edge rounding cross belts. The opposite rotation enables the edge rounding of all the contours: inside and outside. The result after this station is a soft edge.

This deburring machine features a magnetic table with 600mm width section. This area is essential for small steel parts processing to guarantee that even with substantial debarring pressure the parts will not move.

DM1100 DC machine includes as standard an automatic thickness measurement. The news developed system enables to easily slide the laser beam through the conveyor ti select the spot where the measurement will be done. The information of the thickness is sent directly to the PLC. There is also the possibility of integrating extra stations for oxide removal or even double side edge rounding.

If you need more information about this machine please send an email to marketing@nsmaquinas.pt or contact us through contact page.